Elevating product design with PEEK plastic injection molding

As a manufacturer, selecting the right material or combination of materials when designing a product is a challenge in itself, especially if you want to ensure its durability and reliability. This selection is all the more crucial in certain industries, such as medical and aerospace, where lives are at stake. In the field of plastic injection molding, PEEK, or polyetheretherketone, is the material of choice for meeting stringent requirements, given its incredible resistance and ability to withstand extreme environments. Let’s take a closer look at the features and benefits of PEEK plastic injection molding.

Key Takeaways

- PEEK (polyetheretherketone) is a high-performance thermoplastic with exceptional properties, including high mechanical strength, excellent temperature resistance, and strong chemical resistance.

- PEEK injection molding offers significant advantages over metals and other plastics, including weight reduction, long-term cost-effectiveness, and sustainability benefits.

- Aerospace, automotive, medical, oil and gas, and electronics are the industries that most benefit from PEEK injection-molded parts.

What is PEEK material?

PEEK (polyetheretherketone) is a high-performance, semi-crystalline thermoplastic polymer that belongs to the family of polyketone polymers known as PAEK. These polymers are made up of groups of aryl, ether, and ketone molecules, which contribute different properties to PEEK:

- Aryl and ketone molecules provide hardness and rigidity for good mechanical performance and a high melting point.

- Ether molecules provide flexibility and chemical resistance.

Key characteristics and properties of PEEK

PEEK’s characteristics and properties make it a material of choice for molding precision plastic components in many industries. For example, PEEK’s chemical resistance and bio-inertia make it ideal for plastic injection molding of medical devices. Below, I share with you a list of the main characteristics and properties of PEEK that are essential to know when choosing a material for injection molding.

1. Mechanical strength and dimensional stability

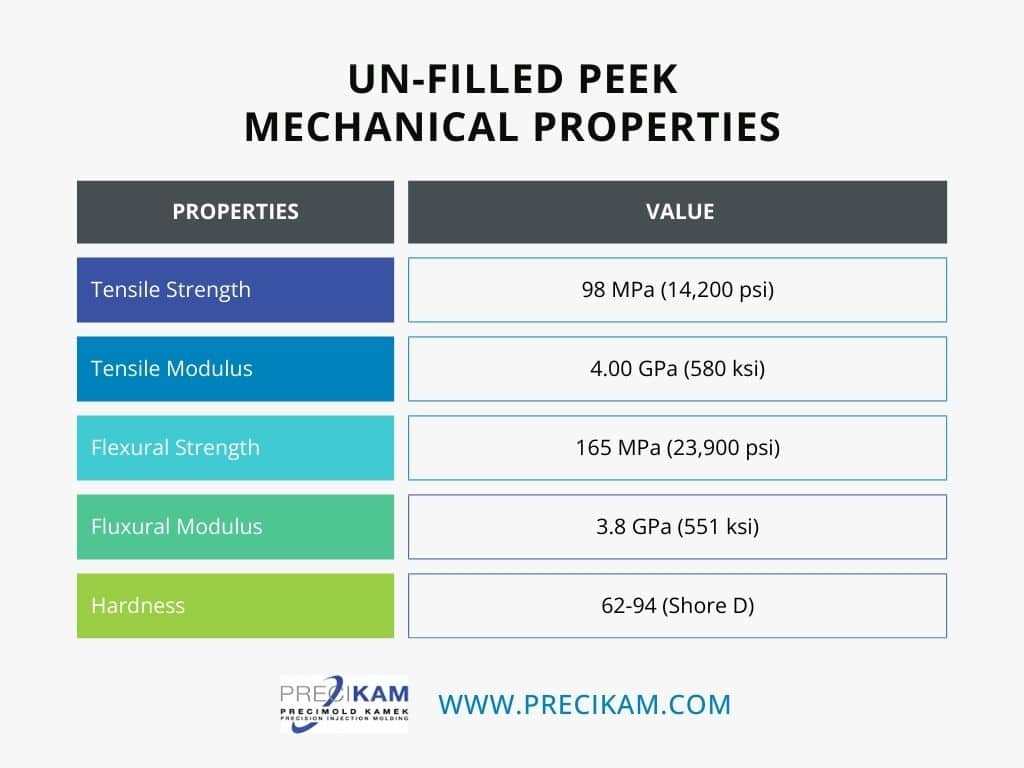

PEEK is a material that offers high mechanical strength and stiffness, even under continuous stress. It can withstand tensile strengths exceeding 14,000 psi (96 MPa), which makes it suitable for demanding environments.

PEEK also excels in wear resistance, with friction coefficients as low as 0.1, ensuring long-lasting performance.

This injection molding material also resists creep, keeping its shape under load. At around 260°C, its creep resistance remains stable, with a minimal strain of less than 0.1% over 2000 hours of continuous loading. However, you can analyze a significant decrease in the creep resistance to 1160 psi (8 MPa) at high temperatures (>260°C).

Table of mechanical properties of un-filled PEEK material

2. High-temperature performance

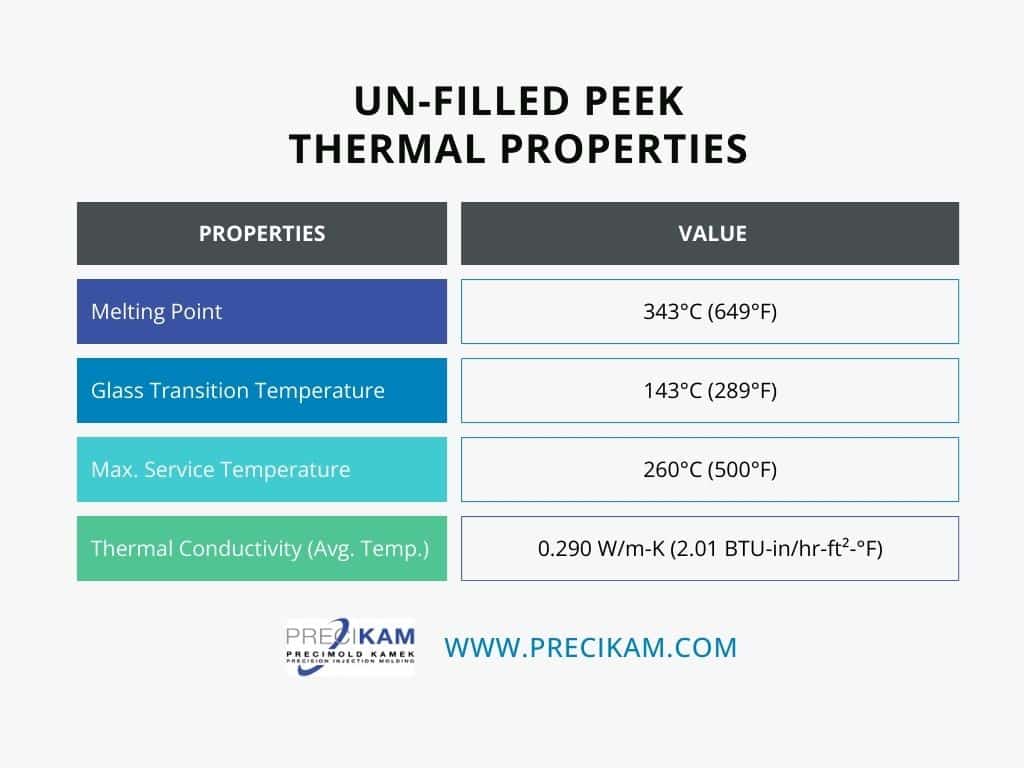

PEEK stands out when you need a material that can handle extreme heat. It’s built for high-temperature environments with a melting point of 343°C and a glass transition temperature of 143°C. Even at 260°C, PEEK retains 50% of its original strength.

Without worrying about performance loss, you can rely on this material for continuous use in hot water, steam, or other harsh conditions. This makes it a great choice for industries where consistent reliability under high temperatures is key.

PEEK injection molded parts have a thermal conductivity of 0.290 W/m-K. PEEK’s ability to conduct heat efficiently adds another layer of durability and performance to your design

Table of thermal properties of un-filled PEEK material

3. Resistance to harsh chemicals and corrosion

Polyether ether ketone (PEEK) offers exceptional resistance to a wide range of organic and inorganic substances, including strong acids, bases, and aggressive solvents. Its chemical inertness enables it to retain its structural integrity and performance when exposed to hydrocarbons, aromatics, ketones, and halogenated compounds. PEEK’s resistance also extends to oxidizing agents such as hydrogen peroxide and chlorine, making it suitable for applications in bleaching and sterilization processes.

Additionally, you can rely on PEEK for its hydrolysis resistance as it performs well in steam, water, and seawater. It remains stable in wet environments with a low water absorption rate of 0.45%.

In summary, PEEK is ideal for industries where frequent exposure to chemicals and water is common, such as oil & gas, chemical processing, automotive, marine, food, and medical.

4. Flammability

Looking for a durable material that ensures safety in critical applications? PEEK should be your choice. It is inherently flame-resistant and has a UL 94 V-0 flammability rating, making it a safe choice for high-risk environments. PEEK also emits very low levels of smoke and toxic gases during combustion.

5. High purity and bio-inert

The medical industry relies heavily on PEEK due to its high purity and bio-inert properties. Its low outgassing and minimal leachability ensure cleanliness in sensitive environments. It is also resistant to gamma and electron beam radiation.

PEEK injection-molded precision plastic components don’t react with biological tissues or fluids, ensuring long-term stability and compatibility. Polyetheretherketone also remains transparent to X-rays, making it ideal for implants and devices that require diagnostic visibility.

Advantages of PEEK plastic injection molding

Polyetheretherketone (PEEK) is a material with exceptional properties that is more and more adopted by various industries, as it easily replaces metals and other plastics in many applications. When it comes to plastic injection molding, PEEK offers numerous advantages.

1. Comparison with other materials

The advantages of comparing PEEK to metals and other plastics are clear. Polyetheretherketone (PEEK) is lighter than metals like stainless steel and aluminum, offering weight savings of up to 70%. Despite being lightweight, PEEK maintains high durability, handling temperatures up to 260°C, while aluminum and steel can lose strength in certain high-heat applications.

Unlike some metals that corrode, PEEK also resists a wide range of chemicals. It offers better wear resistance, higher temperature tolerance, and longer-lasting performance in extreme conditions than other plastics.

2. Cost-effectiveness in the long run

When you compare PEEK with other materials, the long-term savings are obvious. Take nylon, for example. A nylon part may cost you $30 initially but will need to be replaced every two months in a continuous working environment. On the other hand, the same part in PEEK will cost you $100 but will last up to 24 months without replacement. As you can see, over time, using PEEK saves on both downtime and maintenance, making it a smarter investment.

Note: The values are just for your understanding!

3. Weight savings and fuel efficiency

PEEK parts offer significant weight savings compared to metals. A component made from stainless steel might weigh 100 pounds, while the same part made from PEEK could weigh just 30 pounds. This 70% weight reduction is crucial in industries like automotive and aerospace, where lighter components improve fuel efficiency and overall performance.

4. Sustainability

When it comes to sustainability, PEEK stands out as a recyclable material. This material is also halogen-free and RoHS-compliant, making it an eco-friendly manufacturing choice. By choosing PEEK for injection molding, you’re enhancing performance and making a responsible, sustainable choice.

Factors Influencing PEEK Injection Molding Cost

When calculating the cost of PEEK plastic injection molding, PreciKam takes the following factors into account:

- Material grade: The cost of PEEK varies by grade and depends on the material’s specific properties. Higher grades designed for extreme environments, like those reinforced with carbon fiber, tend to be more expensive than standard unfilled PEEK.

- Part complexity: Complex part designs require more advanced tooling and longer mold cycles. Intricate geometries can slow the process and increase costs due to the need for specialized molds, additional processing steps, or enhanced cooling.

- Production volume: Higher production volumes generally reduce per-part costs. Molding large quantities allows for better cost distribution over the tooling, setup, and operational expenses.

- Secondary operations: Additional processes such as machining, assembly, or surface treatments increase the overall cost. These are essential when tight tolerances or custom finishes are needed.

- Quality requirements: Tighter tolerances or advanced testing increase production costs. Ensuring your PEEK parts meet industry-specific standards requires extra steps, such as precision inspections or quality certifications.

- Market factors: Global supply chain issues, such as raw material shortages or increased demand, can cause price fluctuations. At PreciKam, we stay on top of market conditions that may have an impact on PEEK’s availability and cost.

Each factor is critical in determining the final cost of your PEEK injection molded parts. Balancing them effectively can help optimize both performance and budget.

Which industries benefit most from PEEK injection molded parts?

Many industries rely on polyetheretherketone injection molding due to its unique properties like heat resistance and durability. Here are just a few.

- Aerospace: Aerospace requires materials that withstand high temperatures, wear, and chemicals. In aerospace plastic injection molding, PEEK is commonly used due to its strength and lightweight properties, improving fuel efficiency. Common PEEK parts include bushings, brackets, seals, and connectors.

- Automotive: PEEK’s ability to handle high temperatures and wear makes it perfect for automotive engines and fuel systems. PEEK parts include bearings, gears, seals, and housings, helping improve vehicle performance.

- Medical: The polyetheretherketone is biocompatible, which makes it ideal for medical devices and implants. Its ability to endure sterilization processes is why it’s commonly used in clean room injection molding environments. It is used to manufacture spinal implants, surgical instruments, and dental abutments.

- Oil and Gas: PEEK’s resistance to chemicals and extreme heat is critical in the oil and gas industry. PEEK injection molded parts include valve components, seals, and pump housings.

- Electronics: The material’s electrical insulation properties make it suitable for high-performance electronic devices. Common parts include connectors, circuit boards, and insulation components.

PEEK’s performance ensures reliability and long-term durability, driving innovation and efficiency across various sectors.

Conclusion

PEEK plastic injection molding is a powerful tool for elevating product design across multiple industries. Its superior strength, lightweight properties, and heat resistance offer designers the flexibility to create durable and high-performing components. Whether you’re in the aerospace, automotive, or medical fields, PEEK provides long-lasting reliability while promoting innovation and efficiency in product development.

Precikam specializes in precision plastic injection molding, from aerospace components to medical devices. Our clean room and ISO 13485 injection molding facilities ensure top-quality results for even the most demanding applications. Contact us to discover how our expertise can assist you with your product design.

About Jack McDonald

Jack McDonald is the President of PreciKam, a leading North American precision plastic injection molding manufacturer based in Baie-d’Urfé, Quebec. With over three decades of industry experience, Jack is dedicated to producing quality precision molded plastic parts crucial to health and safety in the medical, automotive, and food sectors.

Follow Us